Last Updated on April 21, 2024 by Saira Farman

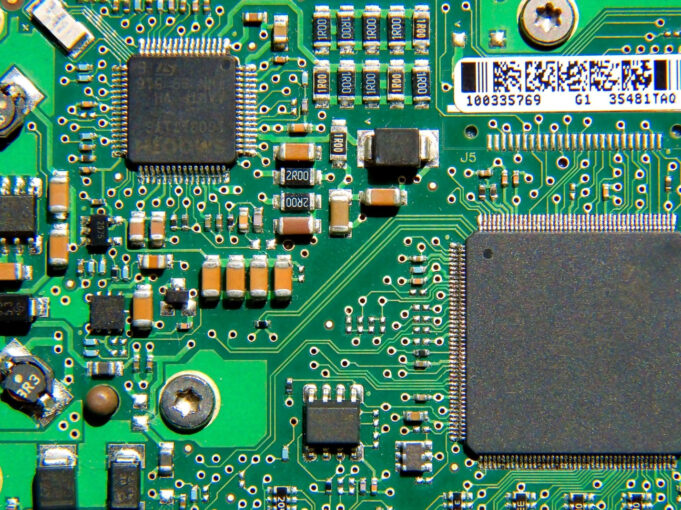

Printed Circuit Boards or pcb are the things that get classified into diverse types based on manufacturing processes, design stipulations, and application requirements like automotive, medical, defence, and space. So, More complicated designs grounded on the needs of consumers and requirements pave the way for manufacturing diverse types of PCB boards. Before you even pick a PCB, you should look for a few considerations such as the space required. Overall stress handling, and mechanical as well as electrical stability. Of course, once you have the right pcb design service, they can help you with your choices.

A few of the diverse types of pcb available are like:

- Single-Sided pcb

- Double-Sided pcb

- Rigid pcb

- Multilayer pcbs

- Flex pcbs

Have a detailed look at all these types so that you can make a better choice.

Single-Sided pcbs

A single-sided PCB is the commonest kind of printed circuit board. It includes a single conductive copper layer above the overall substrate. The electrical components are solder or even keep on one side of the board. So, the whole etched circuit stays visible on the other. Since such types of boards just have one conducting layer. So, The conductive paths cannot simply intersect or overlap and hence take up so much of space.

As an outcome, these pcbs are apt for low-density design requirements. Single-sided printed circuit boards (pcbs) are somewhat used for basic and low-expense electrical/electronic instruments. Like calculators, power supplies, even LED lighting boards, FM radios, timing circuits, and even so on.

Perks of Single-Sided pcbs

- Absolutely cost-effective

- Easy to manufacture

- Perfect for low-density type of designs

- Convenient to repair in case anything goes wrong

- Convenient to design

Double-Sided pcbs

A thin layer of forming material, such as copper, is added to both the overall top and bottom sides of the board in a double-sided type of PCB. Holes in the circuit board enables metal parts to get connect from one side to even the other. These pcbs link up the circuits on either side making use of one of two mounting methods. Through-hole technology or even surface mount technology. Through-hole technology involves installing lead components into pre-drilled type of holes on the circuit board. Which are then fuse to pads on opposite sides. Surface mount technology involves the precise placement of electrical components on the overall surface of circuit boards.

You know, these double-sided pcbs get extensively use in a diversity of applications. Like cell phone systems, test equipment, power monitoring, amplifiers, HVAC application, UPS system, and even many more. Once you speak with pcb manufacturing company, you will get them all.

Perks of Double-Sided pcbs

- Diminishes size which makes circuit compact

- Apt for advanced electronic systems

- More flexible

- Comparatively lower cost

- Enhanced circuit density

Rigid pcbs

As the name says it all , a rigid PCB is simply a circuit board that cannot get twist or even folded. The board’s base material is a rigid type of substrate, that gives the board rigidity and strength. These are compose of numerous layers including a substrate layer, a solder mask layer, a copper layer. And even a silk screen layer that are followed together with adhesive as well as heat. Although some circuit boards are somewhat either single-sided, double-sided, or even multi-layered, rigid pcbs could be any of these relying on the overall requirements. However, remember that once they are made, they cannot get modify or even altered.

Rigid pcbs get use in GPS equipment, laptops, computer, tablets, mobile phones, X-rays, heart monitors, MRI systems, CAT scans, temperature sensors, control tower instrumentation, and more.

Perks of Rigid pcbs

- Lightweight

- Cost-effective

- Convenient to diagnostics & repair

- Low electronic noise

- Absolutely lightweight

- Ability to absorb vibrations

- Compact

Multi-Layer pcbs

Multilayer pcbs own more than two copper layers. In general sense, any board featuring as a minimum of three conductive layers is encompass in this category. Multilayer pcbs are design in a ‘sandwich’ sort of fashion. With numerous double-sided conductive layers forked by an equal number of insulating material sheets. All of such must be bond as well as laminate together under high pressures. And temperatures to simply ensure that no air gaps exist and even that the final PCB assembly is correctly stable.

Multi-layer pcbs get use in computers, laptops, tablets, mobile phones, medical equipment, GPS trackers, and even numerous other more complex circuits and devices.

Perks of Multi-Layer pcbs

- Compact in size

- More powerful

- High degree of design flexibility

- Apt for high-speed circuits

Flex pcbs

A flexible printed circuit board is type of board that is make up of numerous printed circuits. As well as components that get arrange on a flexible substrate. Flexible pcbs are generally make from polyamide, PEEK (Polyether ether ketone), or even a transparent type of conductive polyester film. Flex circuit boards, flex circuits, flex pcbs, and versatile printed circuits are other sorts of names for these kinds circuit boards. Such printed circuit boards are formed up using the same components as rigid printed type of circuit boards. The prime distinction is that the board gets designed to flex to the desire form across the application. These pcbs are there in double-sided, single-sided, and multilayer configurations. So, This contributes to a discount in the difficulty of the unit assembly.

Moreover, you know Flex pcbs get use in organic light emitting diode (OLED) fabrication, LCD fabrication, even flex solar cell, automotive industries, cellular telephones, cameras, and even complicate electronics products like laptop computers.

Perks of Flex pcbs

- Save space

- Eliminate connectors

- Thermal management

- Apt for applications where high signal trace density is require

- Enhanced reliability and repeatability

- Offers uniform electrical characteristics for high-speed type of circuitry

Conclusion

To sum up, the point is simple, Once picking a PCB manufacturing partner ponder. About expense optimization, adequate material usage, overall delivery time, and even more. Whether designing embedded system or anything else, the right expert manufactures can get you exactly what you need.