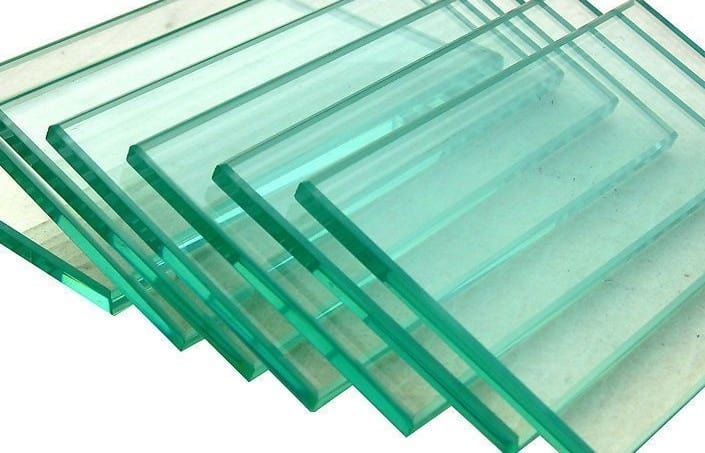

Toughened glass is a type of safety glass that is stronger than standard glass. In contrast, laminated glass is much weaker, which can result in the protected area of the glass becoming exposed. For this reason, Toughened Glass is preferable over laminated glass.

Laminated Glass

When considering replacement windows, there are two main types: toughened and laminated. Toughened glass is stronger than laminated glass, but it can also be more fragile. Laminated glass has an added layer of protection: plastic or PVB, which protects the glass from intruders and harsh weather conditions. However, it’s also more expensive than tempered glass, and fewer manufacturers offer it. The interlayer is visible if you look at the glass edge.

Laminated glass is better for car windows than standard toughened glass shopfronts. This type of glass is better at resisting impact because it maintains its place when shattered. It also offers superior sound proofing and UV resistance.

Tempered Glass

If you are concerned about the safety of your windows, you should invest in tempered glass instead of standard glass. These types of windows are made with a special manufacturing process that aims to make them stronger. The process involves intense heating and cooling. The result is tempered glass, which is about four times more durable than standard glass.

One reason why tempered glass is better than standard glass is its higher tensile strength. This strength is a measurement of how much load a sheet of glass can withstand when stretched. Standard glass has a tensile strength of only 1,000 pounds per square inch, while tempered glass has a tensile strength of 10,000 pounds per square inch. While this strength isn’t the only factor that determines how strong a piece of glass is, it’s one of the most important. Because tempered glass has a higher tensile strength, it is harder to break than standard glass.

Annealed GLASS

The process of annealing glass is used to improve the toughness of glass and extend its lifespan. Compared to standard glass, annealed glass has fewer internal stresses, making it less likely to break and maintain its shape. Annealed glass is often used in laminated glass because of its strength and flexibility.

Annealed glass is the most common type of glass used in most household objects. It is 100% clear and provides high levels of transparency. It is an economical choice for low-cost remodeling projects, but it should be handled with care. It can be fragile if dropped, so it is not a good choice for locations with high foot traffic.

Tempered glass, on the other hand, is stronger than annealed glass. This type of glass undergoes a special heating treatment and cooling process to make it stronger. This allows the glass to be cut, drilled, and fabricated without breaking. It is used in projects with safety needs, such as shower enclosures, facades, and office partitions.

Heat-Treated Glass

The process of heat-treating glass produces a number of physical changes, including a reduction in opacity and an increase in tensile strength. This process also improves glass’s ability to resist thermal shock. However, it is important to note that heat-treated glass can produce optical distortion. As a result, it is important to consult the manufacturer or seek approval before installing it in your project.

To produce heat-treated glass, annealed glass is cut to the desired size. The glass is then heated to over 1,150 degrees Fahrenheit. At the same time, air is forced onto the surface, creating a high compression of the surface and compensating tension within the core. The process doesn’t change the overall properties of glass, and it does not affect its durability, but it can improve its resistance to thermal stress.

Heat-Strengthened Glass

Heat-strengthened glass is a superior material to standard glass because of its superior strength and durability. It is about twice as tough as annealed glass. Moreover, this material does not shatter like standard glass. This means that it is more resilient to impact and less likely to form dangerous shards.

It is commonly used in general glazing applications, especially in buildings that are subject to high wind loads. However, it cannot be used in safety glazing applications, such as shower doors and storefronts. It is mainly used in architectural projects and for commercial glazing. It can withstand higher thermal and mechanical stress. https://www.barkingshutters.co.uk/glass-shopfronts-in-london/

Tempered glass, also known as toughened glass, is manufactured by heating annealed glass to 700 degrees Celsius and then force-cooling it at an accelerated rate. This results in a glass with increased surface compression and four to five times the resistance to breakage. Furthermore, it does not produce large fragments, making it safer to use in buildings.